About Us

About Us We are an independent business unit of TEDOM a.s. with a production plant in Jablonec nad Nisou. Our tradition dates back to 1906. We currently have over 150 employees and manufacture or modify around 450 engines per year.

We develop and manufacture combustion engines under our own brand TEDOM for cogeneration units, railway vehicles and for special uses.

We modify and rebuild combustion engines of renowned manufacturers SCANIA, MAN, LIEBHERR and KUBOTA.

We renovate technical units of internal combustion engines and perform their general repairs.

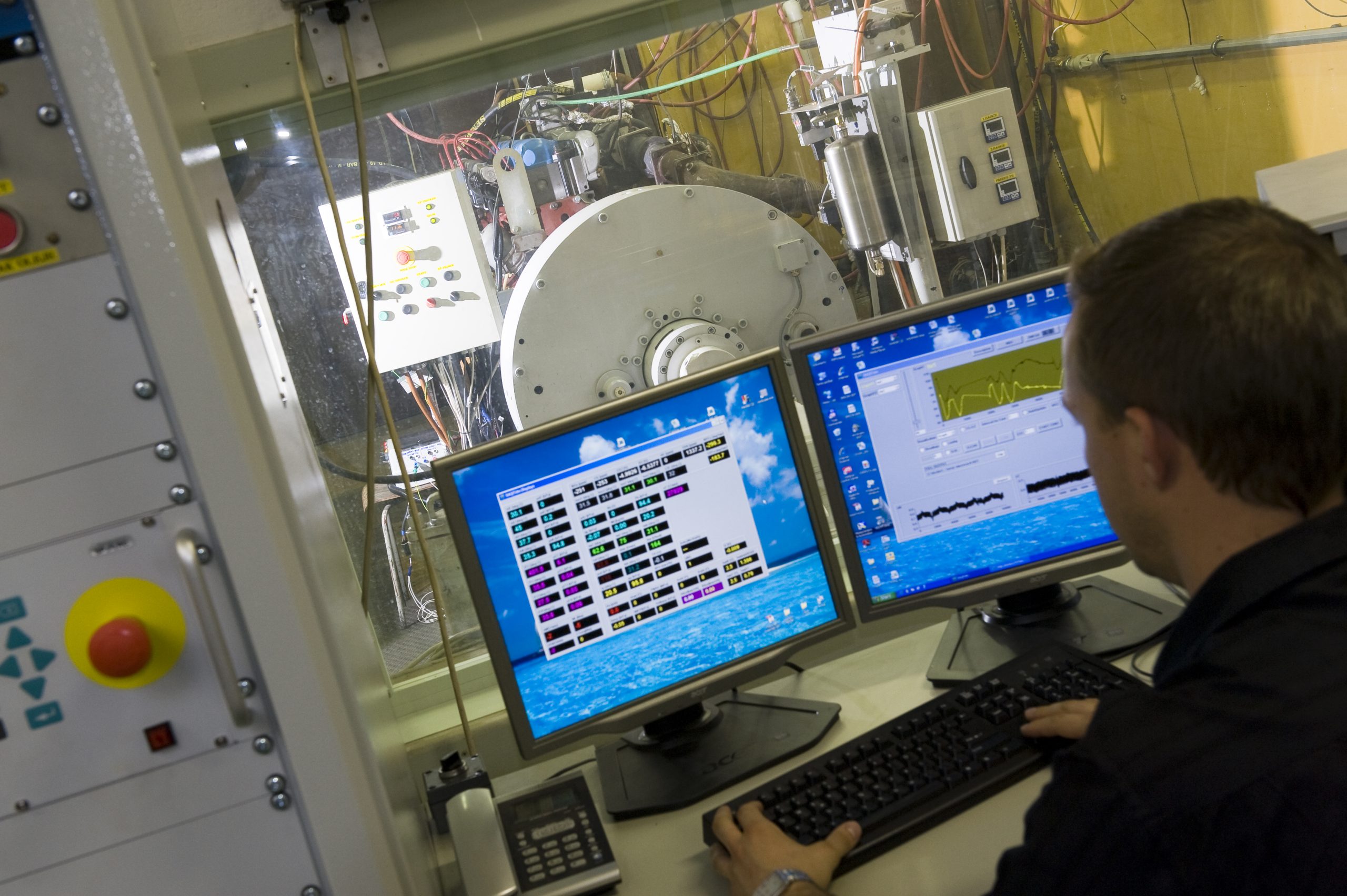

We have our own development and construction facilities, a fully equipped test room and our own production facilities for the installation of new engines, as well as for the overhaul and renovation of engines or their parts.

Company history

Company history  Development and production

Development and production The development and implementation team of experts works on the design and production of reliable modern motors for mobile and stationary use.

Our own development department, equipped with state-of-the-art technology for measuring the technical parameters of engines, including the reduction of harmful emissions in exhaust gases, is working intensively on the short-term and long-term goals of TEDOM Engines. In particular, it is a matter of achieving an increase in engine efficiency and the production of lower values of harmful emissions in the exhaust gases with regard to current and future legislative limits.

Meeting the increasingly stringent criteria, especially emissions and economics, is also the reason why the development of engines deals with the possibilities of using alternative fuels from renewable energy sources.

Production takes place on modern CNC machine tools. The machinery and work procedures are continuously modernized.

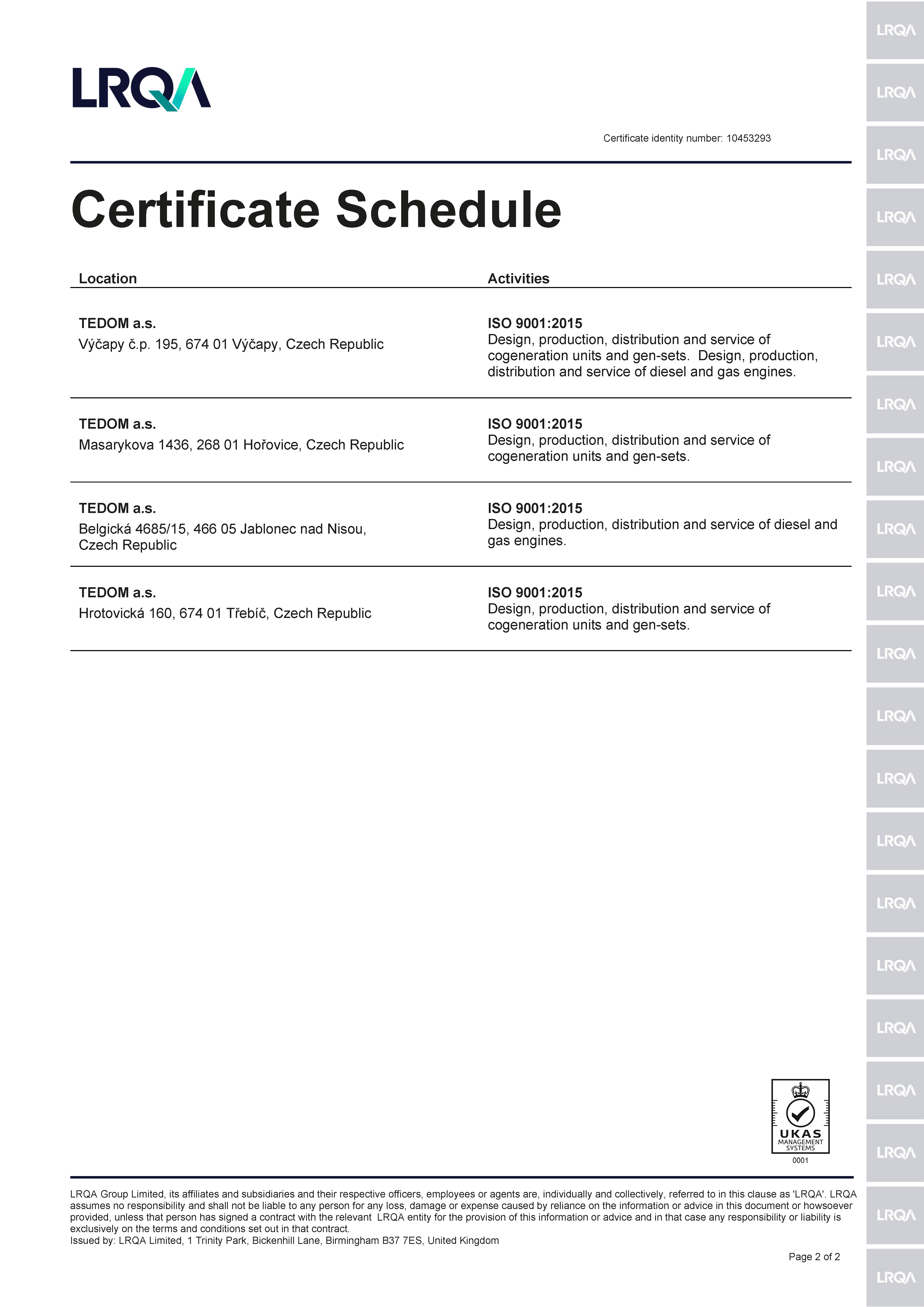

Certified quality management system

Certified quality management system TEDOM Engines has implemented a certified quality management system in accordance with the requirements of the European standard ISO_9001_CZ EN ISO 9001: 2015.

All processes and activities of the company are implemented on the basis of a philosophy of continuous improvement.

Compliance with the ISO 9001: 2015 standard is regularly inspected by the international certification company Lloyd’s Register Quality Assurance.